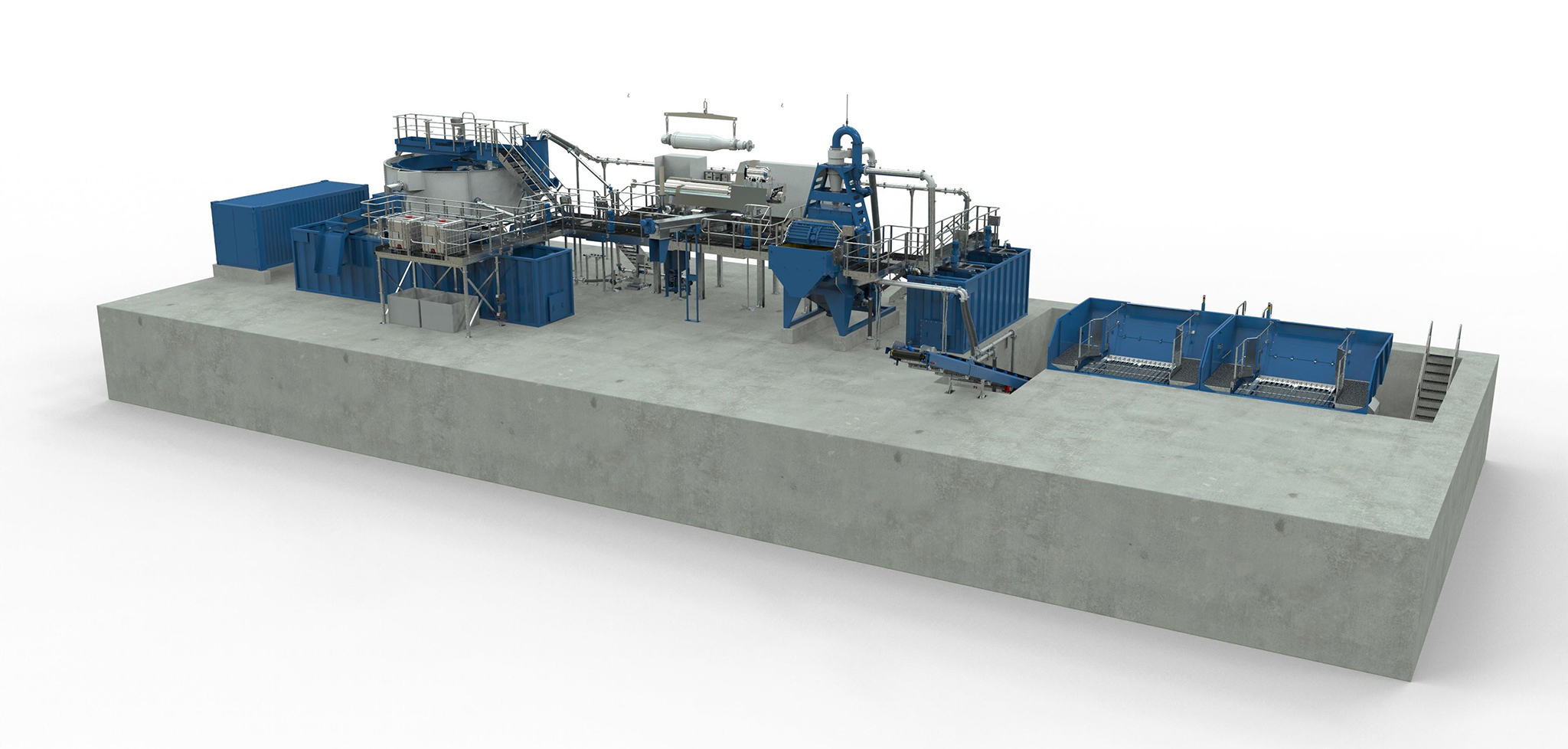

InterGroup is excited to announce construction of our new, state-of-the-art resource recovery facility is well underway at our Auckland premise. This wet processing plant will be equipped with world-leading dewatering technology with the ability to clean and grade aggregate material – providing maximum recovery and diversion from landfill.

New Resource Recovery Facility Construction Underway

Construction of InterGroup’s brand new Resource Recovery Facility is underway!

The Challenge

The New Zealand Infrastructure Commission has found that waste from construction makes up between 40 to 50% of all waste sent to landfill – around 4.4 million tonnes annually from construction and demolition sources.

InterGroup, as a leading provider of industrial and infrastructure services to local and central government and private entities, is invested in improving waste diversion through our activities and across the sector.

Waste generated by street sweeping and hydro excavation activities in particular pose challenges when it comes to disposal. This is due to the mixing of materials and contamination levels. To mitigate this, InterGroup has invested in a number of dewatering plants in recent years, going some way toward reducing the volume of waste we send to landfill. However, these plants are limited in their capability to support recycling and reuse. Given this, InterGroup has thoroughly investigated options to improve our waste management – and to contribute to improved environmental outcomes across the sector.

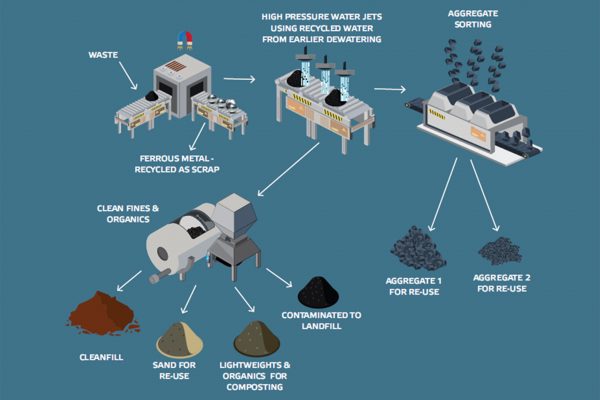

A Schematic Snapshot of Our Future Facility

Our Solution

InterGroup is constructing an industry-leading resource recovery facility at our Stonedon premise. The technology we have incorporated is world-leading, and a first for New Zealand, with:

- A dedicated tipping station to ensure maximum dewatering and processing of slurried waste materials. This will produce clean reusable sand, aggregate, and water products.

- A water cleaning and treatment system which allows up to 90% of process water to be recycled and immediately re-used within the plant.

- A scrubbing and filtration system that carries out pre-screening, scrubbing, organics removal, sizing, stockpiling, fines recovery and filtrates removal; and

- A two-stage separation and classification system which includes high-pressure washing to effectively remove contaminants and provide the highest possible quality of final products.

For us, and our customers, this will result in enhanced recycling outcomes and an impactful contribution to achieving waste reduction targets.

The Key Benefits Of Our Facility

- Partnering with CDE means our facility benefits from the guidance, technology and innovation of global leaders in materials wet processing. CDE has refined their knowledge and products over 30 years in business and delivered over 2000 waste processing projects worldwide.

- As NZ’s leading wet processing plant it will provide the opportunity to reuse material avoiding disposal to fill facilities.

- The ability to reuse materials in infrastructure activities will contribute to greener construction.

- Will support enhanced environmental outcomes with tangible reductions to align with our customer’s environmental targets and support industry wide targets.

Why Choose Us?

This facility is more than just a dewatering plant. It is a comprehensive solution which will clean and process solids – transforming them into high-quality aggregate and sand. These outputs can then be reused on projects.

Employing the most innovative technology on the market, supplied by CDE – global leaders in wet processing solutions for waste recycling and mineral processing – this facility will support maximum retrieval and reuse, and will ensure InterGroup’s new waste processing facility sets the standard in the New Zealand market.